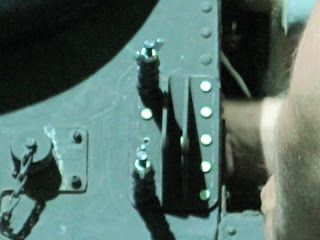

With many hours of measuring, drilling, sweating and swearing, we got the new bracket drilled to the proper location and started to install 11 new Hilocks. As you can see from this picture, the space is rather limited. Behind that panel that you see, is a bunch of wires, bolts, nuts, and other various parts that rub against the skin and take up a lot of room.

In this picture, you can see that there is really no way to go at this in a comfortable position. Phillips, (The other guy in my shop) and I had to switch out after every couple Hilocks. The reason for this is because the collars on the Hilock has a hex head on one end and is flat on the other end. The flat end threads on the Hilock, and you use a wrench on the hex end to finish installing the collar. Once the collar gets to a certian tourque, the hex head snaps off, leaving the collar on the Hilock. Well, the issue with this is, the Hilocks have a tendency to spin. So, in the end of the Hilock, opposite of the head, is a hex key hole. You have to put an allen wrench inside the hole, hold the hex key, and turn the wrench all at the same time, and all on the same end. As you can see, I am only using one hand. That is because there is barely room for one hand on the inside of this project. So, one hand got to do the job of two hands. Let's just say, it took a while.

This was started on Tuesday, at 16:00, (4:00pm). We stopped for the night at 20:00 (8:00pm). Wednesday, my day off, I was at work by 05:45am. Phillips and I did not leave untill 01:45 Thursday morning. In other words, Phillips pulled an 18 hour shift, and I pulled a 20 hour shift. Today is my day off for the week, and I am VERY tired.